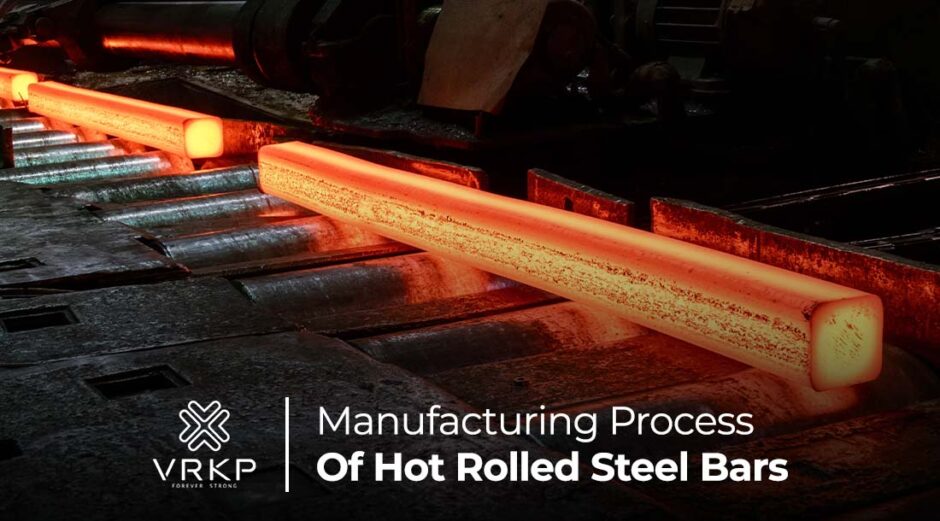

Manufacturing Process Of Hot Rolled Steel Bars

Hot rolling is a method used to produce flat- and long-rolled steel. Since it needs less force and energy, hot-rolled steel is the most popular. Under this method, the metal is rolled at a temperature above the recrystallization temperature, which is above 1000oC for steel.

The process begins with steel billets or slabs. Steel slabs from casting plants get conditioned in a reheating furnace. It is followed by steel rolling. Scale breakers remove scales( a kind of oxide) from the surface of the steel slab.

Using an Automatic Width Control (AWC) system, an edger rolls the slab into rolled materials with the proper shape, thickness, and width.

Finishing Rolling adjusts the width and thickness of a coil to the specified level to make a smooth surface and shape, making it suitable for specific use.

To coil steel strips, they are passed to the run-out table. The strips get sprayed with water to cool them to the optimal coiling temperature when it is rolled on the table.

Hot-rolled steel is used extensively to make support structures for large construction projects and the engineering industry, where surface quality and high-dimensional accuracy is not a concern. Usually seen in

- Pipes and tubes

- Truck frames

- Constructions

- Railway tracks

- Doors and shelves

- Railroad car parts

Hot-rolled steel is easy to process and produce in larger quantities than cold-rolled steel. Strip-casting plants are becoming a better choice for global producers because it combines steel casting and hot rolling into one process saving on production speed.